snelle details

conditie: nieuw

Voltage: 220V / 380V

Afmeting (L*W*H): aangepast

Gewicht: 3500kg

Certificering: CE ISO

Garantie: 2 jaar

Service na verkoop: ondersteuning van derden beschikbaar

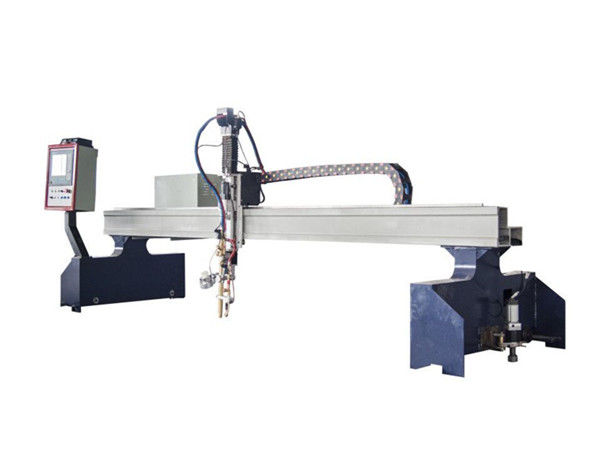

Type: portaaltype

Kleur: aanpasbaar

Machine kenmerken

o Door gebruik te maken van een zeer nauwkeurige lineaire geleiderail en een dubbelzijdig motoraandrijfsysteem werkt de machine geruisloos met hoge snelheid en hoge precisie;

o De CNC-plasmasnijders van de Hypertherm Powermax-serie hebben gebruiksvriendelijke bedieningsinterfaces, gedetailleerde informatie met gemarkeerde knoppen en zijn eenvoudig te leren en te bedienen;

o De machines hebben de functie om automatisch te onthouden en te herstellen wanneer de stroom is uitgeschakeld;

o De machine is ook voorzien van automatische boogspanningstoortshoogteregeling, deze kan de snijafstand automatisch aanpassen.

Parameters van de machine:

Model | U-PC 3060 Plasma vlam snijmachine |

Machinale snijmaat: | 3000x6000mm (andere maten zijn aangepast) |

Snijmodus | Plasma en vlammen |

Vlam snijdikte | 5-150 mm koolstofstaal |

Hypertherm 200A snijdikte | 60 mm in theorie |

Motoren en chauffeurs | Japanse Yaskawa of Panasonic |

Snijsnelheid | 0-3500 mm per minuut |

Nauwkeurigheid van de positionering | 0.02mm |

Nauwkeurigheid plasmasnijden | 0.2mm |

Machinespanning: | 220V |

Hypertherm 200A plasma voedingsspanning | 380V |

Transmissiesysteem | Hoge precisie lineaire geleiderails, tandwiel- en tandheugeltransmissie |

Z: automatische boogspanningsregeling | |

Controle systeem | FL-besturingssysteem |

Software ondersteuning | FASTCAM, AutoCAD, etc |

Instructie formaat | G-code |

Plasma voeding | VS Hypertherm 105A/125A/200A |

Hardwareconfiguratie van het besturingssysteem

1).MCU:ARM9

2). Aantal asbewegingen: bewegingsinterpolatie met twee assen (kan worden uitgebreid tot drie assen)

3). Max. coderegels: 150.000 regels;

4). Enkele snijcode: 4 MB;

5). Bestandsgeheugenruimte:: Elektronische bulkgeheugenchip, 512 MB

6). Geheugenruimte gebruikersbestand: 256 MB

7). Controlerende nauwkeurigheid: ± 0,001 mm (millimeter)

8). Coördinatenbereik: ± 99999,99 mm

9). Max pulsfrequentie: 250 KHz; Max bewegingssnelheid: 25 m/sec.

10). Tijdoplossend vermogen: 10ms

11). Systeemvermogen: DC +24V

12). Werkende staat van het systeem: Temperatuur: 0℃ - +55℃; Relatieve vochtigheid: 0-95%.

13). Interface: USB

14). Frame: algemene metalen structuur, bestand tegen elektromagnetische straling, anti-interferentie, antistatisch

15). Speciale configuratie: Touchpad, 100 m draadloze afstandsbediening en draadbedieningskast (optioneel voor het volledige bereik van de F2000-serie)

16). Ondersteuning zuurstofgas, plasma, poeder en simulatie demo-modus.

17). Toetsenbord: PCB-filmtoetsenbord, PS/2-interface, OMRON-knop

Kenmerken van het besturingssysteem:

1). 45 categorieën verschillende afbeeldingen (inclusief rasterpatroon), chipgedeelte en gatgedeelte zijn alternatief.

2). Afbeeldingen hebben een aantal bewerkingen zoals Proportion, Rotate, Mirror.

3). Afbeeldingen kunnen worden gerangschikt in matrix-, interactie-, gestapelde modi

4). Afhankelijk van de plaatdikte wordt de snijsnelheid automatisch beperkt door een snelheidslimiet in de hoek, waardoor oververbranding effectief wordt voorkomen.

5). Metrische systeem/imperia systeem schakelaar

6). Stalen plaat kan worden aangepast aan elke stalen zijde.

7). Het coördinatensysteem kan worden aangepast om de tweedimensionale coördinaten van alle acht soorten te ondersteunen.

8). Alle invoer- en uitvoerpoorttypen en het aantal kan worden aangepast (normaal open of normaal gesloten)

9). Back-up van systeem en parameters, systeem online bijwerken

10). Chinees / Engels (inclusief Japans, Russisch, Frans en andere talen) bestandssysteem en menu kunnen slechts met één toets worden geschakeld.

11). Selecteer rij en kolom handmatig.

12). Ondersteuning randsnijden en offset snijden.

13). Onthoud automatisch de werksituatie en het laatste snijpunt bij het uitschakelen.

14). Dynamische/statische illustratie van het proces, grafische in- en uitzoomen, dynamisch volgen van het afkappunt onder zoomstatus.

15). Stel verschillende beheerdersbevoegdheden in en het bijbehorende wachtwoord om de belangen van managers te beschermen.